National Post from Toronto, Ontario, Canada • 18

- Publication:

- National Posti

- Location:

- Toronto, Ontario, Canada

- Issue Date:

- Page:

- 18

Extracted Article Text (OCR)

July 19, 1941 A -O. UNO I 5. Science Develops New Fabrics to Replace or Supplement Old -ZNOF THE AGEH Discovered through the magic oi blending STAPLON! The first improvement in knitting yarn in more than 30 years I A sensational development, created by Lewis Limited to meet the demand ior a really better, tougher yarn! It took years of research, it took the magic of blending, to combine the natural long fibres of combed wool with laboratory produced fibres which make STAPLON possible. But Lewis Limited have done it and this amazing new yam unshrinkable, soft, durable, warm, moth-repellent is now on the market. STAPLON, in a wide variety of forms, will soon be avail, able in all types of men's wear and throughout the textile industry for hosiery, underwear, knitted and woven fabrics wherever wool was formerly used.

It combiner the warmth and flexibility of natural wool with the strength and durability of scientifically produced fibres. STAPLON is as modem as plastics, television, air conditioning. It brings to the woollen textile industry what Nyloa brought to hosiery, what tetra-ethyl brought to gasoline. 'STAPLON is tho ultimata ia yarn perfection. Textiles made entirely from pure silk, one stage in the handling of being shut'vout of the Canadian market by wartime which is illustrated here, are restrictions.

Canadian Induttriri Ltd. Photo LEWIS LIMITED Head Oifice and Factories: Truro, Nova Scotia, Canada Now manufactured in ladies? skirts by Travellers Shirts limited, Truro, in hosiery by Leuis limited; in sweaters byRennie Industries Limited, Toronto, Ontario. Watch for the growing list of products and uses. U. S.

Cellulose Acetaie Output Records Gain U. S. cellulose acetate production in the form of sheets, rods and tubes registered a seasonal increase in May, amounting to 524,393 lb. and bringing the total for the year to date to 2,351,616 lb. Output, however, continues to run behind "last year, when production in May total the semi-textile trade, ribbon-like strips and in a variety of larger sec tions.

Saran has high tensile strength, is non-flammable and re sistant to light, water, acids, alkalis and most solvents. So far it has been used chiefly in weaving of seat cov ers for transportation equipment, theatres, restaurants and homes. Milk as a Fibre Fibre has been derived from the casein oi rmiK ana nas recenuy emerged from the experimental stage. It is used at present in the commercial field for hat felts. Soy bean fibres, although still largely laboratory products, may reach the commercial stage in the United States soon.

These fibres have about 80 of the strength of wool. When it comes to discussing the uses' to which these synthetic fibres are put, not much need be said about rayon. Everyone is familiar with men's and women's underwear, dresses, socks, linings for all purposes, draperies and other house furnishings made from rayon. Particularly in women's apparel, cloth made from rayon yarns has achieved a dominant position. 1 Rayon Use prows New uses for rayon have been found in such things as the cord for heavy duty tires recently.

The new rayon staple fibre has broadened the field and, blended with other fibres or by itself, is now being spun and woven into suitings and overcoatings, which sometimes compete directly with woollens and worsted fibres. Rayon staple is invading the rug and carpet industry, particularly when the imported wools from which carpets have been made get difficult to obtain and high in price. Staple fibre rugs are offered regularly, particularly in the United States. Silk Substitute Nylon's greatest use so far lies in the manufacture of full-fashioned hosiery. Sewing thread and fishing New fibres for use in textiles are-fr achieving considerable prominence.

Some of these, such as rayons, are not really new but only improvements and new forms for what used to be known as "artificial silk" when it was first manufactured about 1898 in France. Others are entirely new in the past few years, have received a lot of publicity, and have proved themselves to the extent that they are particularly adapted for certain uses and substitutes for other well-known textiles. Nylon, introduced commercially in 1939, is probably the "best publicized of the more recent synthetic fibres. Vinyon, glass, casein and soy bean fibres are other new synthetics which may assume increasing importance in search for new and improved textiles, as well as substitutes for others which are becoming scarce, or where the supply is threatened. Two Major Processes Although there have been four recognized processes for making rayon yarn, only two are in general use today In the viscose process, cellulose obtained from cotton linters or wood pulp is first subjected to a solution of caustic soda, treated with carbon bisulphide and, after some other processing, is forced through fine orifices or spinnerets, into a fixing bath where the filaments solidify.

In the acetate process of making rayon, the cellulose is treated with a mixture of acetic acid, sulphuric and acetic anhydride. The product is dissolved in acetone, forced through spinnerets and solidifies as fine filaments which require no washing or bleaching. Acetate yarns have been increasing in popularity and in 1940 accounted for about 34 of rayon yarn production in the United States. Staple Fibre. Rayon staple fibre Is a development in the rayon field which is becoming a major phase of the industry.

It is used for the manufacture of spun rayon and blended fabrics. In contrastwith the continuous filament rayon, rayon staple fibre is made by cutting rayon filaments to' the desired short lengths. These short lengths, after any necessary washing and bleaching, may be spun into yarn on cotton, silk, or wool spinning machinery, thus giving a wide variation in the texture and other qualities of the finished product. Some authorities estimate that the consumption of rayon staple fibre will eventually exceed that of the continuous filament rayon based on recent rapid rate of growth. Nylon Manufacture Nylon is made from nylon "salt" produced from elements and com pounds derived from air, coal and water.

Like rayon it is forced through spinnerets to form filaments, which solidify upon exposure to the air. and then twisted into nylon yarn. Nylon has an elastic recovery of 100 when released from a stretch of compared with a recovery of 50 for silk and acetate rayon and 30 for viscose rayon. When dry. nylon is stronger than silk and it ab sorbs relatively less water than wool.

viscose rayon and silk. Nylon is dif- ficult to burn, does not mildew eas ily and has little attraction for mold and moths. Vinyon is a plastic made from derivatives of coal or natural gas, salt, water and air, and known as vinylite resin. It is dispersed in acetone and forced through spinnerets to form the filaments. Vinyon can be pro duced in staple fibre form.

It is water repellent, almost as strong wet as dry, and not attacked by bacteria molds or fungi. It is extremely re sistant to most strong acids and alka lis at ordinary temperatures but softens when heated to a temperature above 150 degrees Fahrenheit. Cloth From Glass Fibreglas, drawn from molten glass, is produced in both the continuous filament and staple fibre form. It is incombustible, durable, non-absorbent, and does not absorb moisture. Extremely flexible and resilient, fibreglas has a strength exceeding that of the strongest steel piano wire.

Saran, another new synthetic, is made from a product known as vinylidine chloride secured from crude oil and brine. It can be made in various forms such as filaments for TEXTiLE H40 Txtil Stocks Cfcart iy Tht Ftnmciet I 1939 I the war Before has influenced here nmg well below the general Tno war ine led 702,385 lb. and for the first five months 3,304,992 lb. Cellulose acetate production in the form of molding composition, on the other hand, shows a sharp increase this year compared with 1940. During May output totalled 2,319,133 lb.

bringing accumulative production to 10,315,967 lb. for 1941. During May last year. 893,374 lb. of composition were produced, making a total for the first five months of 5,096,686 lb.

i'tt ,) -I 1 J.rf lines made from nylon yarn have been on the market for some time, while nylon glove fabrics and foundation garments are now appearing in the United States. With future price and supplies of raw silk uncertain, nylon might establish itself in other luxury fields such as ladies undergarments, expensive gowns and laces and men's fine neckties. The United States Army has been reported as pleased with the results of experiments with the performance of parachutes made from nylon yarn. Extension of the use of nylon appears to depend upon two things, its price and productive capacity of the plants. Original prices for yarns for wimen's hosiery were set at $4.27 to $4.55 a pound, but already price reductions have been made.

Production of nylon is still small in the United States, only place where it is being made although a Canadian factory is due to start late this year or early next year, and can only supply 10 to" 15 of the full-fashioned hosiery sales. As a comparison viscose rayon in 1917, early in its career, was priced at $4.25 a pound for first quality yarns. The price is now 53 cents. Vinyon and Fibreglas So far vinyon has been used chiefly in the manufacture industrial felts, cloths, ducks and pile fabrics. Possible uses include full-fashioned hosiery, shoe fabrics, curtains, braided and knit goods, sail cloths and others.

Because the yarn does not support combustion and fuses at a low temperature, it has been mentioned as a material for airplane cloth. Fibreglas is becoming important in electrical insulation where glass tapes are employed to wind coils and glass sheets are replacing cotton and asbestos in motor generators and transformers. In the home fibreglas is used in bedspreads, tablecloths and draperies. Not All In Canada The only one of these fibres at nt thr share prices was run- the situation is reversed. present widely used and made in Canada is rayon.

Canada is a large producer of the i high-grade wood duId. an" essential aw material in making For the other synthetic fibres men tioned, nylon is fairly well known in the form of women's hosiery in Can ada but supplies have been strictly limited so far. Some Canadian plants are experimenting with casein fibres. What the future of these fibres will be in Canada during wartime is hard to say. On one hand we have the rieed for substitutes for silk and on the other hand we have little diS' position to experiment witn un known fibres in wartime.

Rayon is well known and widely used. Nylon is recognized as having certain uses for which it is well adapted. It is lack of supplies which is holding back development of the latter. Textile's Tax Bill Trebled (Continued from page 13) 45.7. Working capital shows moderate gain of 5.6.

Primary cotton operators experi enced a gain of nearly 50 in gross income, or $5.3 millions. Taxes took an additional $5.4 millions, or $100, 000 more than the operators took In. A similar situation prevailed for the woollen group, while the silk group reported earnings practically unchanged, but an increase in taxes of around $425,000. In respect to knit goods, convert ers, carpet and miscellaneous manu facturers, the returns indicate that the gain in income was just about sufficient to cover the higher taxes payable to the Dominion Govern ment, -r As the situation now stands the textile c6mpanies may have diffi culty in maintaining share profits in 1941. Plant operations are close to effective capacity, so that little is to be gained in the way of lowering overhead charges.

Meanwliile costs of material and labor are advanc mg. Of still greater importance xs the further increase in taxes which means operators in the textile in dustry (and other industries for that matter) 'will find it difficult to boost net income this year. Clothing Canada's Fighting Forces (Continued from page 13) making the cost of dyes at least 30 to 40 above pre-war levels. Canadian producers are doing an excellent job in providing the chemicals ranging from salt, sulphuric acid and caustic soda to highly complex specialty chemicals which the textile industry needs. With the United States supplies still available, no particular difficulty has been encountered by, the industry.

In still other ways the ordinary consumer in Canada is going to find the war influencing his textile supplies. For instance, the mixtures of wool in the wool and cotton goods available wilf contain less wool and more cotton. Artificial and synthetic fibres will replace many natural products, particularly silk, wool and to some extent cotton. Mofe and more, Canadian women are going to wear dresses made from a blend of rayon and wool or all rayon. Canadian mills have developed this product to a high standard and it is meeting with good acceptance.

Wages Aggregate $60 Millions Wages paid by the primary textile industry in 1939, the last year for which complete returns are available, totalled nearly $60 millions. By divisions this sum was divided as follows: cotton, $18.5 millions; hosiery and knit goods, $17.8 millions; wool, $10.5 millions; rayon, $8 millions; dyeing and finishing, $1.1 million and others, $3.9 millions. Capital Invested $255 Millions Capital invested in Canada's primary textile manufacturing industries amounts to over $255 millions. In all there are 509 establishments and the value of their peacetime output was $226 millions yearly. mm 1 rw Avf Synthetic Yarns Set Pace (CANADIAN SYNTHETIC FILAMENT YARN PRODUCTION AND IMPORTATIONS OF RAYON YARNS AND STAPLE FIBRE) (Calendar Years 1925 to 1940)-: In thousands of pounds the corresponding four months cf 1940.

Canadian Pacific lines in Maine recorded net operating income of $562,161 in the four month period, compared with $450,645. Canadian Pacific lines in Vermont recorded a net operating deficit of $111,434, compared with a deflcit ef $141,648 last year. Central Vermont showed a net operating income of $372,832, against $201,407 last year. 1 Vital Contributions ftllT fAffl CCCftDT Canadian Rails in U. S.

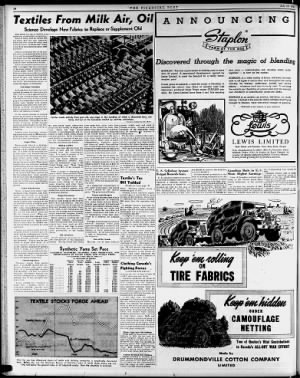

Show Higher Earnings Lines of Canadian railways operating in the United States have shown betterment in the current year. In the first four months of 1941, Canadian National lines operating in New England pared net operating deficit to $184,285 from $267,245 in i ior- a UNDER 7 Two of Quebec's I an 1 ON i Viscose Acetate Total. Staple Canadian Yarn Yarn Produc- Yarn Fibre Supply Year Output Output tion Imports Imports Total 1925 507 507 1.851 2,359 1926 1.921 1.921 1.365 3,287 1927 2,512 2.513 1,615 4,128 198 3,153 203 3,356 2,031 5,888 1929 3,280 403 3.684 2.221 5,906 1930 3.535 1,091 4,627 2,383 7,011 1931 4.376 1,495 5.871 1,780 7,652 1932 5.197 2,127 7.325 1.088 8,413 1933 4.567 2.766 7434 .1.757 9,091 1934 6.718 3.832 10,550 1.210 11,761 1935 8,467 4,748 13,215 1,214 14.430 1936 8,064 5.557 13.622 1.167 14,790 1937 10.173 6,325 16,498 2,022 18,520 1938 7.204 6,500 13,704 1.756 15,461 1939 7.697 6,500 14.197 3.128 2.569 19.895 1940 12,637 7,200 19,837 3,482 4,180 27,500 STOCKS FOSGE AHEAD iw vaiiaua 9 hllvu i wmii uiiwi est 1940 Made by DRUAAAAONDVILLE COTTON COMPANY LIMITED shares of textile and clothing companies is graphically illustrated dominion Bureau or statistic indo index of all industrial stocks. Now I T..

Get access to Newspapers.com

- The largest online newspaper archive

- 300+ newspapers from the 1700's - 2000's

- Millions of additional pages added every month

Publisher Extra® Newspapers

- Exclusive licensed content from premium publishers like the National Post

- Archives through last month

- Continually updated

About National Post Archive

- Pages Available:

- 856,989

- Years Available:

- 1907-2024