The Odessa American from Odessa, Texas • 111

- Publication:

- The Odessa Americani

- Location:

- Odessa, Texas

- Issue Date:

- Page:

- 111

Extracted Article Text (OCR)

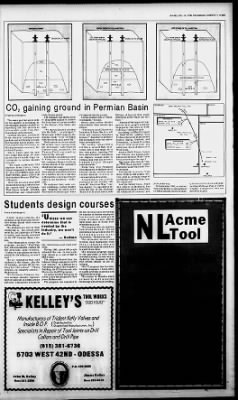

Sunday, Oct. 14, 1984 THE ODESSA AMERICA 11H VWERRJDOCMNG EARLY STAGE OF CO, INJECTION LATE STAGE OF CO, EJECTION 4 CRUDE OIL TO SALES C02 FROM SHEEP MOUNTAIN PIPELINE CRUDE OIL TO SALI 1 CO, FROM SHEEP roi irc "mi r-rt MOUNTAIN PIPELINE 3i SEPARATION PLANt 4 OIL CCD WATER OIL CO, MISCIBLE BANK OF C02 OIL CO, OIL I MISCIB OIL WATER CO COLORADO Sheep Moon fin CO 2 Field C02 gaining ground in Permian Basin costs, Brown added. The company has spent a total of about $900 million to initiate the first flood of carbon dioxide to the Denver City fields, she said. "We started limited injection into the field. mid-April," Brown said.

At full capacity, the pipeline holds "over 10 trillion cubic feet of natural, pure C02." Shell expects to recover about 280 million more barrels from the previously water-flooded Denver Unit, located in the Wasson Field surrounding Denver City, she said. Ken Kelley, president of Jack B. Kelley Inc. of Amarillo, said his company began trucking carbon dioxide to its customers about two years ago. "Production companies have been using it in limited activities for a number of years, but only in the last five years has it really come to the forefront," Kelley said.

He explained that, under certain conditions, carbon dioxide gas "expands so much more than water or natural gas" when NEW MEXICO OWNERSHIP ARCO OIL SAS 30 50 CXXON U.S. A SANTA FE Bravo Dome CO Cat Field OWNERSHIP ARCO OIL 15 EXXON U.S.A 35 AMERADA HESS 30 jects under way. In September 1983, a contract was awarded for construction of a carbon dioxide recovery facili From Staff Reports The same gas that gives soda its fizz rapidly is becoming an increasingly popular method of squeezing the last barrels of recoverable crude from Permian Basin oil formations. Carbon dioxide, produced from natural underground pockets and artificially in fossil fuel-burning power plants, has been used locally for tertiary, or third-generation recovery, for atleast 11 years. But is wasn't until the past five years that large oil companies have made huge investments in carbon dioxide recovery.

"We built a 500-mile C02 pipleine from Cortez, almost diagonally to Denver City" at a cost of $480 million, said Mary Brown, public affairs officer for Shell Western Inc. of Houston. Shell also invested about $200 million to develop a carbon dioxide "source field" in Colorado. That figure includes drilling, dehydration and compression CO OIL KANSAS OKLAHOMA TEXAS Fw 1 ield Wasson Field Seminole Field HOBBSl SEMINOLE MIDLAND ty to be installed at Union Texas' existing Wellman Plan in Terry County. Completion was expected in August.

ti I i Students design OIL CO billions of barrels that would otherwise never reach the surface." "Almost all the larger oil companies have people actively engaged in this area of work right now," Rosebery said. According to a March 1 report by Shell Oil Co. entitled "C02 Tertiary Recovery in the United States: Status, Outlook, and Economics," at least 21 carbon dioxide field pilot tests are under way. Seven of those are in WestTexas. Amoco, Shell, Exxon, Conoco and Chevron are among companies involved in West Texas tests, according to the report.

Th report also cites 16 "ma-jor'C02 flood profect" either planned or under way in the Permian Basin. Estimated recovery from those fields is 600 million barrels, with an average range of prof itabity from 12 to 15 percent, the report said. And the Ortloff which has offices in Midland, has reported two major carbon dioxide enhanced oil recovery pro- i 111 i 1 il II 1 UVl cr WATER it's injected into the ground. Carbon dioxide also is "readily available," he said. Brown said carbon dioxide mixes better than natural gas with oil.

"The theory is as C02 goes in a formation it fizzes like in a soft drink and restores formation pressure" depleted by primary and secondary recovery operations, she explained. The reaction "allows C02 to act like a solvent that overcomes forces that traps oil in tiny rock pores. Injecting C02 into waterflooded formations can displace enough water to contact, mix with and mobilize trapped oil once thought unrecoverable." Elcor Corp. Vice President Dick Rosebery of Midland noted several recent articles about carbon dioxide recovery in various trade publications. According to one article published in the October 1983 issue of "American Way," carbon dioxide "is expected to extend the life of the Permian Basin 30 or 40 years and to yield courses the last several years, increasing the number of Odessa employees from two to six.

And, while only 16 weeks of classes were offered eight years ago, 45 weeks were scheduled this year. The program attracts students from all over the world. "It's not uncommon for us to look like the United Nations in our classrooms," Hudson has said. The extension service also recruits class instructors from the oil industry who are sometimes brought in to teach only a part of one class. The extension program began in the mid-1940s to offer field-oriented training.

Odessa was included in the program in 1954, with offices located on the OC campus. The UT program has two other training campuses. A home office in Austin provides materials and administrative needs. The center in Houston deals primarily with pipeline technology and off-shore drilling. BOX 6685 Jimmy Kelley IUs: 382-6410 i r.

ljzD From Staff Reports Unlike mosts schools, the students at the Petroleum Extension School decide what courses will be offered. The students are sent by their employers to the school sponsored by the University of Texas at Austin, and recently relocated on the UT Permian Basin campus. "They themselves design the programs, we don't," Paul Hudson, who coordinates classes for the program, said recently. "Unless we can determine that is needed by the industry, we won't doit." The oil companies that send students to the classes, plus the oil industry, provide all the funding for the school. "These schools are industry schools," Hudson said.

The Petroleum Extension Service surveys industry representatives to decide on needs, and an advisory committee evaluates 'II nless we can determine that is needed by the industry, we won't doit.1 Hudson the instructors. and class contents. During 1983, about 600 people attended the one- to four-week-long classes at a cost of $250 to $800 a class. The program Tnoved from the Odessa College campus to UTPB last summer. In addition to a remodeled wing of the Founder's Building, the UT System set aside 20 acres for the PES program.

An indoor drilling site on the 20. acres is now the program's show piece, Hudson said. The program has expanded in P.O. I V7 V79 tool works Ef? LaLSILILIUS "D0ESY0URS" Manufacturers. of Trident Kelly Valves and Indrla RHP A Distributed by IIIOIUU U.w.r.

Diversified Manufacturers Inc. Specialists in Repair of Tool Joints on Drill Collars and Drill Pipe (915)381-6736 5703 WEST 42CJD ODESSA John M. Kelley fUs: 381-2355.

Get access to Newspapers.com

- The largest online newspaper archive

- 300+ newspapers from the 1700's - 2000's

- Millions of additional pages added every month

Publisher Extra® Newspapers

- Exclusive licensed content from premium publishers like the The Odessa American

- Archives through last month

- Continually updated

About The Odessa American Archive

- Pages Available:

- 1,523,072

- Years Available:

- 1929-2024